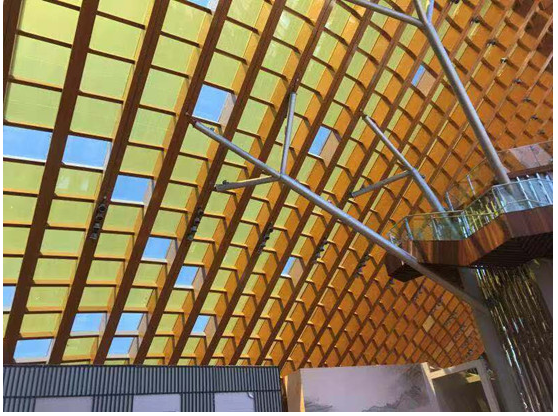

The picture shows the China Pavilion of the Beijing World Garden Fair using cadmium telluride thin film color transparent photovoltaic glass

It's the season when osmanthus fragrance we visited Advanced Solar Power(Hangzhou) Inc.(ASP), accompanied by the sweet fragrance of osmanthus, the reporter realized what is "all the way to hangzhou ", but also in the interview unconsciously unveiled ASP's cadmium telluride film components.

Steady progress Better than bigger

ASP founded in 2008, has established a vision of "independent innovation, China's creation" since its inception, and has focused on the research and production of cadmium telluride thin film module. At present, the company covers high-end equipment manufacturing, production technology export, raw material supply, photovoltaic power station investment and operation," five-in-one "technology industry chain. Not only successfully break the foreign technology monopoly, but also take the lead in domestic realization of cadmium telluride thin film solar technology industrialization.

For the development of photovoltaic industry, ASP’s chairman and chief technology officer Prof. Xuanzhi We said that the global building energy consumption is about 28% of all energy consumption, and the construction has become the three major energy users alongside industry and transportation. Green low-carbon development in the construction field is an important way to achieve the goal of "beautiful China ". On Jan.24, 2019r, the Ministry of Housing and Urban-Rural Development issued the "Notice on the Issuance of the National Standard," Technical Standards for Near-Non-Non-Energy Consumption Construction. The near zero energy consumption building technical standard GB/T51350-2019 also came into effect on September 1, in which case the transition from "energy-saving building" to "capacity building" is imperative. On top of that, Prof. Wu, who has been studying solar-cell technology for nearly 40 years, has given the answer to his "mission" at the age of 79. He said that the reason why has been engaged in the photovoltaic industry, one is because like, the other is because our country's energy situation is becoming increasingly severe, vigorously develop renewable energy is everyone's mission.

Everyone has his own personality, and so does the enterprise. ASP from beginning to end adhere to the "first strong after the big" development road. Mr. Ben Wu,CEO of ASP, said that "first strong and then big" is the development line set by his father Prof.Xuanzhi Wu. Since its establishment in 2008, the company from the experimental line, pilot line began to cadmium telluride thin film solar cell industrialization technology research and development. In 2011, ASP built the first fully automated cadmium telluride battery production line with fully independent intellectual property rights and mass production capacity, realizing the localization of industrialization technology of cadmium telluride thin film photovoltaic cells. In 2014, the conversion efficiency of cadmium telluride battery products manufactured by ASP reached 13%, and entered the international advanced level. In 2015, ASP as the main undertaking unit, undertook the Ministry of Science and Technology during the 12th Five-Year Plan 863 advanced energy technology field related to cadmium telluride thin film solar cell technology industrialization project. In 2018, ASP combined with shenzhen seig group, sheneng south control company built and put into production in Hangzhou a new generation of fully independent research and development of cadmium telluride thin film photovoltaic cell production line, design capacity of 40 mw, mass production battery module average power of 95 watts, the average photoelectric conversion efficiency of 14%. It can be said that ASP people every step is down-to-earth, the interpretation of the "first strong after the big" concept.

Innovation to be Stronger in BIPV

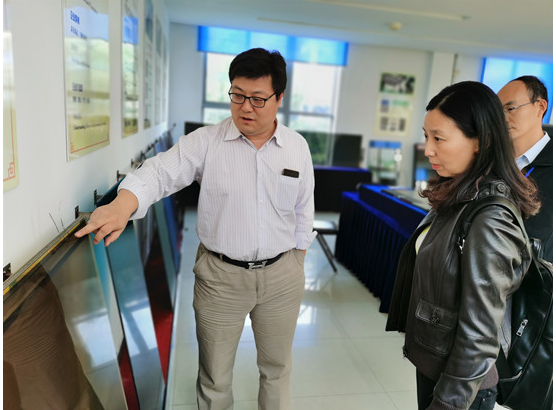

To understand an enterprise, not only to understand its ideas, but also to understand its products. For a more intuitive understanding of the cadmium telluride film photovoltaic glass, Mr Ben Wu took reporters to visit the company's production line. In the production workshop, the reporter saw the coded conductive glass placed at the first end, in the automated production line these conductive glass after more than 20 processes, a variety of automation equipment on the glass substrate plated with 10 layers of thin film composed of different materials, these materials will form the front electrode, the absorption layer and the back electrode on the substrate, until the end with another ordinary flat glass laminated package, a cadmium telluride film assembly is not counted as finished production.

'Most of the photovoltaic industry has similar technology and similar products, but cadmium telluride thin film technology is only industrialised in one company in the United States,' Mr. Ben Wu said. Therefore, in the process of development, ASP must continue to explore, in order to master this technology from the process, equipment to raw materials. At present, the company has developed a series of new products not only to achieve distinctive characteristics, but also to achieve "no one I have, people have I superior." Because in ASP, only differentiated competition business is lasting, and price competition will only push themselves to keep costs down.

In addition to technological innovation, ASP focuses on the research of photovoltaic architecture integration. Because in ASP, photovoltaic materials not only assume the power generation function, but also the building function, the photoelectric curtain wall in addition to the power generation function, but also the curtain wall function, the most important point is to serve the building.

According to Mr Ben Wu, traditional solar modules give people the first impression of solar panels made up of small blocks of blue and black, This kind of silicon solar panel is used in architecture, usually independent of building components, and cannot achieve the integrated design with architecture, so it is difficult to meet the architect's requirements for architectural form and effect. The absorbing layer of a thin solar cell is very thin, ranging in thickness from several hundred nanometers to several microns. The average crystalline silicon solar cell is 150 to 200 microns thick, nearly 100 times the thickness of the absorbing layer of a thin film solar cell. Therefore, compared with the silicon cell, the thin film photovoltaic power generation glass is easier to realize the building photovoltaic integration. ASP thin film photovoltaic glass, is a new photovoltaic module. This kind of power glass is the perfect combination of building function and power generation effect by integrating a thin film into a special toughened glass for building.

Improved projects Demonstrate unique competitiveness

Visited the Beijing World Horticultural Expo China Museum, the reporter was attracted by ASP 1024 cadmium telluride film color transparent photovoltaic glass. To ASP, this silent contribution to the development of the new energy industry in the enterprise has deeply touched the heart of the reporter.

In addition to the 68-year-old founding ASP, today still working 12 hours a day, ASP has a high-quality talent team, strong technical force. The core technicians are the world's top scientists in the photovoltaic industry, with rich technical research and development, engineering practice experience and new energy technology integrated service capacity.

Mr Ben Wu said that the Beijing expo china pavilion is the world's "top level , competitive products , , difficult" representative of the field of photovoltaic, but also long-term accumulation of energy long-term high-grade, precision, cutting-edge photovoltaic technology perfect embodiment. According to the design requirements of the building, each solar module is fan-shaped, with different shapes, difficult processing and high precision. As a state-level project, the exterior requirements are very strict. The photovoltaic roof should not only meet the needs of indoor lighting, heat preservation and heat insulation, but also meet the function of power generation, and also meet the aesthetic effect of architecture. Under the requirements of three technical indexes, the customizable degree of photovoltaic glass such as multi-size and multi-specification is a process of quantitative change to qualitative change.

In ASP, there are many photovoltaic projects like the China Museum of the World Horticultural Expo in Beijing. So far, longyan energy's cadmium telluride film solar module products have been marketed to 38 countries and regions around the world, covering all provinces, cities. Its highly customized building photovoltaic component products are also installed in the 2022 Beijing Winter Olympic Games venues, National Grand Theater Dance Center, Jiaxing photovoltaic science and technology museum, london canary wharf bus station, swedish hospital and other iconic green buildings at home and abroad on the external structure, all show its unique market competitiveness and comprehensive application value. In the future under the guidance of "understanding, innovation, rigorous, diligent" corporate culture, photovoltaic architecture integration will usher in a beautiful spring.

China Building Materials News Reporter: Yue Wu, Lan Yan,Weina Wang, Audit: Yijie Wang